Our Process

Molding

Molds are the core of metal products, and we possess a comprehensive set of mold manufacturing capabilities including CNC mold processing, tooling, wire cutting, electrical discharge machining, mold surface polishing, and heat treatment of molds. This ensures that our quality is strictly controlled right from the start. Whether the products are flat or three-dimensional, we can complete them in our mold processing center.

Die-casting

Metal die-casting is our specialty. We offer different machine models ranging from 38 tons to 200 tons, along with various mold frames for different sizes and structures, creating diverse die-casting capabilities. We use fully automated robots to ensure stable production capacity and have a complete exhaust treatment system and metal material recycling equipment, emphasizing environmental protection during manufacturing.

Polishing

Metal surface treatment defines a product's initial tactile impression. We have various techniques including hand polishing, automatic machine polishing, dry polishing, and vibratory polishing to handle products with different appearances and shapes.

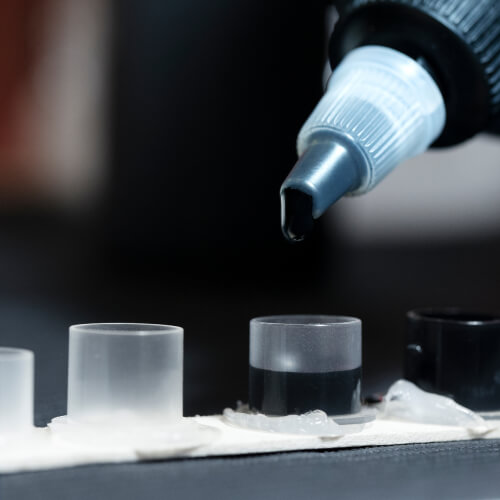

Color-filling

Adding various colors to metal products is one of the technologies we specialize in. We can apply different paint effects to your products such as soft enamel color, hard enamel color, epoxy color, translucent color, glitter color, marbleized color, glow-in-the-dark color, etc. In addition to traditional manual coloring, we also use new fully automated coloring equipment to ensure that we can meet customer demands in terms of production capacity and quality.

Plating

Our advanced electroplating equipment is a key strength in our metal manufacturing process. Electroplating is an indispensable process in metal manufacturing. Within our own electroplating workshop, we can ensure good quality control and consistent metal color. We can provide effects like gold, imitation gold, nickel, black nickel, chrome, brass, copper, various antique finishes, matte finishes, etc. We also have complete wastewater treatment facilities to ensure that every drop of discharged water meets national standards.

Printing

To achieve more refined and detailed color effects, we offer professional silk screen printing and the latest UV printer technology to ensure that every intricate color design can be realized while maintaining cost-effectiveness. We aim to achieve maximum benefits within suitable pricing.

QC

Product quality is one of our top priorities. We conduct rigorous inspections at every stage of the production process, and we maintain the same level of diligence both before and after final packaging to ensure that every product meets customer requirements. We have various testing equipment in place to meet customer quality standards.

Packaging

Product packaging may seem simple, but it is also crucial and should not be underestimated. We accommodate various complex or simple packaging requirements as requested by customers, and we ensure the final mile is flawlessly executed in a clean and bright environment.